Tractor Engine Oil: Key Maintenance Tips for Farm Machinery

Tractor Engine Oil: Key Maintenance Tips for Farm Machinery

Running a productive farm depends on more than just good weather and hard work - it relies on machinery that performs efficiently, day in and day out. Tractor engines, in particular, are the backbone of modern farming operations, powering everything from ploughs to harvesters. To keep them operating smoothly, maintaining your tractor engine oil is essential.

At

Northern Oil, we recognise that high-quality fuels and lubricants are crucial for maintaining your machinery in optimal condition. Whether you’re looking to buy red diesel, find a trusted fuel distributor, or stock up on high-performance tractor oil, we’re here to help farms across Nottingham, Leicestershire, and Derbyshire run efficiently and cost-effectively.

In this guide, we’ll explore the importance of tractor engine oil, how to choose the right type, and how regular maintenance can extend your machinery’s lifespan and save you money in the long run.

Why Tractor Engine Oil Matters

Tractor engine oil plays a vital role in the health and performance of agricultural machinery. It’s much more than just a lubricant - it performs several crucial functions that keep your equipment running smoothly.

It reduces friction between moving parts, preventing excessive wear and extending the engine's lifespan. It also helps to cool the engine by dissipating the heat generated during heavy operation. In addition, quality oil prevents corrosion and rust from forming inside the engine, protecting its internal components. Finally, it acts as a cleaning agent by carrying dirt and contaminants to the oil filter, ensuring the system remains free from harmful debris.

Given the heavy workloads tractors endure, often in harsh conditions, it’s no surprise that oil quality and maintenance have a direct impact on equipment performance and reliability.

Neglecting oil maintenance can lead to reduced fuel efficiency, increased emissions, and, in the worst case, costly engine damage. By using premium-quality tractor oils from trusted fuel distributors like Northern Oil, you protect your investment and ensure your machinery runs smoothly throughout the year.

Choosing the Right Tractor Engine Oil

Selecting the correct oil for your tractor is not a one-size-fits-all process. The right tractor engine oil depends on several factors, including your engine type, manufacturer recommendations, and local climate conditions.

Here are some key points to consider:

Oil Viscosity

Viscosity refers to how thick or thin the oil is at certain temperatures. Tractor oils are graded by numbers like 15W-40 or 10W-30. The first number (with the ‘W’ for winter) shows how the oil performs in cold weather, while the second number indicates performance in high temperatures.

If your tractor is used in colder climates, an oil with a lower ‘W’ rating is ideal for easier cold starts. For heavy-duty summer use, a higher viscosity ensures better protection at high operating temperatures.

API and ACEA Ratings

These are industry standards that indicate the oil’s quality and performance capabilities. Always check that your chosen oil meets or exceeds the manufacturer’s specifications for your tractor model.

Synthetic vs. Mineral Oils

- Mineral oils are affordable and suitable for older engines or lighter workloads.

- Semi-synthetic or fully synthetic oils offer superior protection, better temperature stability, and longer service intervals - ideal for modern, high-performance tractors.

At Northern Oil, we supply a wide range of high-quality Texaco agricultural oils designed for maximum performance and protection, ensuring your equipment runs efficiently no matter the season.

When and How Often to Change Tractor Oil

Regular oil changes are the single most effective way to keep your tractor’s engine in top shape. Most manufacturers recommend changing the oil every 100 to 250 hours of operation, depending on the model and workload.

However, factors such as dust exposure, engine age, and fuel type can all affect oil life. Heavy-duty applications or frequent short trips (where the engine doesn’t fully warm up) may require more frequent changes.

Always replace the oil filter during each oil change. A clogged filter can restrict oil flow, leading to overheating and internal wear.

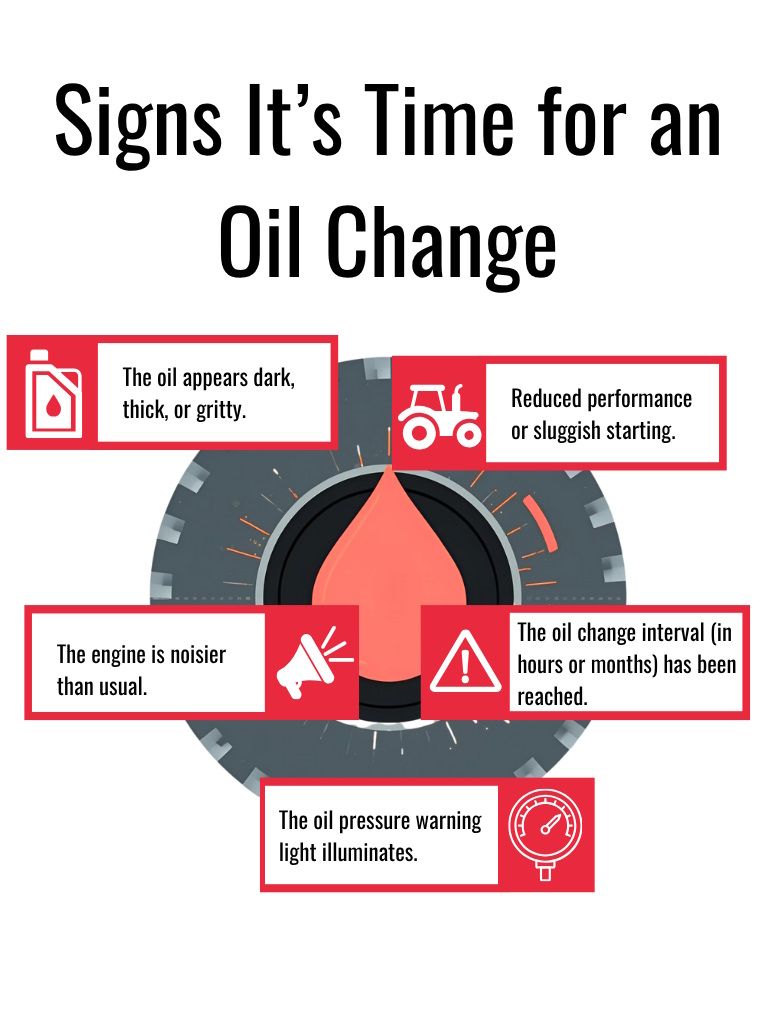

Recognising Oil-Related Issues

Even with regular servicing, issues can still arise if oil quality is poor or maintenance is delayed. Common oil-related problems include:

Overheating

If your tractor frequently overheats, it may be due to old or degraded oil that’s lost its lubricating properties. Overheated oil can also leave carbon deposits inside the engine, reducing efficiency.

Sludge Build-Up

Sludge forms when oil breaks down and mixes with contaminants. It can block oil passages and filters, starving the engine of lubrication. Regular oil changes and the use of premium tractor oils prevent this issue.

Oil Leaks

Look out for leaks around gaskets and seals. These not only cause oil loss but can also lead to contamination of other engine components.

Excessive Oil Consumption

If your tractor consumes more oil than usual, it could signal worn piston rings or valve seals - issues that require professional inspection.

Addressing oil-related issues early helps you avoid major mechanical problems and expensive repairs down the line.

How Engine Oil Affects Fuel Efficiency

High-quality oil doesn’t just protect your engine - it also improves fuel economy. Low-friction lubricants allow engines to run more smoothly, reducing the energy needed to overcome internal resistance.

For farmers using red diesel or other

agricultural fuels, maintaining proper lubrication means getting the most from every litre. Over time, this can significantly reduce fuel costs across your machinery fleet.

At Northern Oil, we don’t just supply tractor oil - we’re also a trusted red diesel supplier, helping farmers access reliable fuel for tractors, generators, and other essential equipment.

Combining Tractor Oil Maintenance with a Fuel Management Strategy

Oil and fuel maintenance go hand in hand. Contaminated or poor-quality fuel can shorten your oil’s lifespan, while dirty oil can reduce fuel efficiency. Implementing a combined maintenance strategy ensures your machinery operates efficiently year-round.

As leading fuel distributors in Nottingham and the surrounding regions, we recommend using clean, filtered fuel from a reliable supplier such as Northern Oil to protect your engine from harmful contaminants. It’s also essential to store diesel in clean, dry tanks to prevent the build-up of moisture, bacteria, or dirt that can affect both fuel and oil quality. Regularly inspecting storage tanks for water and sludge helps to identify early signs of contamination before they cause damage. Finally, maintaining accurate records of oil and filter changes for each piece of equipment provides a clear maintenance history, helping you plan timely servicing and detect any recurring issues.

By combining proper oil care with efficient

fuel management, you’ll improve engine reliability, reduce downtime, and extend the service life of your agricultural machinery.

Extending Equipment Lifespan Through Preventive Maintenance

Preventive maintenance is always more cost-effective than emergency repairs. Regular oil changes, fuel quality checks, and machinery inspections can add years to the life of your tractors and agricultural equipment.

Proper lubrication prevents excessive wear, overheating, and part failure - common causes of expensive breakdowns. Over time, consistent maintenance helps:

- Reduce repair costs.

- Improve performance and fuel efficiency.

- Prevent downtime during critical farming seasons.

- Maintain resale value for machinery.

By choosing high-quality oils and fuels from Northern Oil, you’re not just maintaining your equipment - you’re investing in its long-term performance and reliability.

Keep Your Farm Running Smoothly with Northern Oil

Your machinery is the heartbeat of your farm, and taking care of it starts with choosing the right tractor engine oil and agricultural fuel. Regular maintenance, high-quality lubricants, and a trusted fuel supplier all work together to ensure efficiency, reliability, and performance.

At Northern Oil, we provide everything you need to keep your farm operating at its best, from tractor oil and lubricants to red diesel and fuel additives. With next-day delivery across Nottingham, Derbyshire, and Leicestershire, we’re your reliable local partner for all agricultural fuel and maintenance needs.

Whether you’re maintaining a single tractor or managing a fleet of vehicles, Northern Oil makes it easy to access the fuels and oils you need to keep your farm running smoothly.

Contact us today to place an order or get expert advice on maintaining your farm machinery.